.png?width=770&height=404&quality=100&fit=bounds&dpr=1)

Do you want to know the high production block machines of Poyatos?

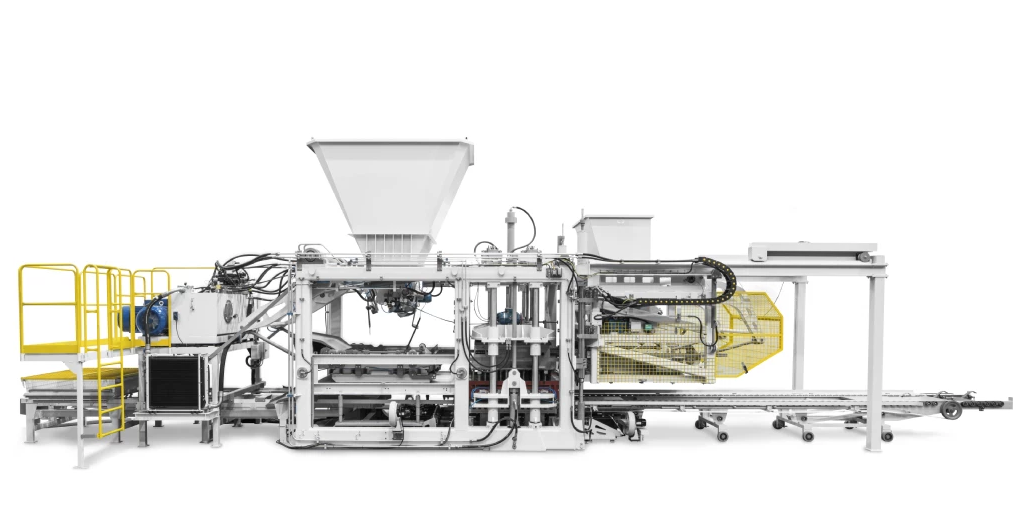

At Poyatos, as suppliers of systems and machinery for the concrete products sector, we provide comprehensive, turnkey solutions for production plants. That is why we offer comprehensive solutions for all types of block and concrete product factories, such as our High production block machines.

We have different machinery, with different production capacities. In today"s article, we want to focus on our three types of high production block machines.

Universal: a completely automatic installation

Our first fully automatic machines. It is the one with the highest production of Poyatos, with only one person necessary for supervision and control, it is the UNIVERSAL block making machine.

Using specialized, easy-to-use software, all production, processing and packaging operations are managed by computer.

As it is a completely automatic installation, a highly optimized factory is achieved, with low energy consumption. The synchronous vibration system of the block machines has proven to be extremely reliable and efficient, as well as very easy to maintain. You can use variable size trays up to 1400 mm. long and 900 mm.

A wide range of options

The line features an automatic finger car with numerous options for transporting parts to the curing chamber, including various floors, loading capacities, rotation options, etc. That is, a wide range of options to modify the installation to the requirements of each project.

It has a fast and automatic electromechanical palletizer along with a central column for packaging.

Novabloc: block making machines with servo-driven vibration system

Novabloc block machines have a servo-driven vibration system that is powered by four servo motors. Additionally, it consists of a vibrating table with four eccentric masses. This system allows complete control over all vibration parameters, including the speed of phase changes, amplitude and frequency.

With dimensions ranging from (1200 - 1400) to (550 - 900) mm, this concrete block machine can be ordered to produce on wood, steel or plastic production boards. It can also be ordered with the option to produce facial blend products.

In addition, this block machine has an automatic fingercar that adapts to the needs of each project in terms of rotating platform, several floors, loading capacity, etc. for handling pallets with products. For production boards, a manual or automatic damping system can be included.

Numerous options available

Depending on the needs of each project, there are numerous options available for removing packages containing items off the line, including slat conveyors, roller rail conveyors, and rail cars.

The owner can also customize the height of the blocks, which ranges from 25mm to 300mm. As well as being able to choose to upgrade to Novabloc with a 400mm increase in block height. In total, about 1500 m2 are needed for the establishment of the plant.

The machine has a maximum force of 98 kN and an air cooling system that keeps the plant cool so it can operate 24 hours a day.

Megabloc: block machines with the highest production capacity

Thanks to its servo-driven vibration system with two vibrating tables, the Megabloc block maker continues to stand out for offering maximum productivity, 18 blocks of 20 cm (8") per cycle (up to 4,500 blocks per hour), allowing balanced mold filling since the vibration parameters on each of the tables are adjusted independently.

The two vibrating tables that make up the servo-driven vibration system each have four servo motors with four eccentric masses. This configuration allows precise control of all vibration parameters, including the speed of phase changes, amplitude, frequency and others.

Production boards High production block machines

Megabloc High production block machines works on production boards that are made of wood, plastic or steel and range between 1200 mm and 1500 mm (47" and 59"). In addition to this, you have the option of having equipment to make face mix items.

Furthermore, the machine has a maximum rated power of 120 kW. Without altering the machinery in any way, the owner can manufacture blocks with heights ranging from 25 mm to 400 mm. These block machines have a cycle time of 12 to 16 seconds. You must have a minimum area of 2000m2 to place the plant. Megabloc has an air conditioning system.