Do you want to give a special finish to your concrete blocks?

So at Poyatos you will find the best machines to offer the best finishes to your concrete blocks. And, all of them with the manufacturing guarantee and the highest quality on the market.

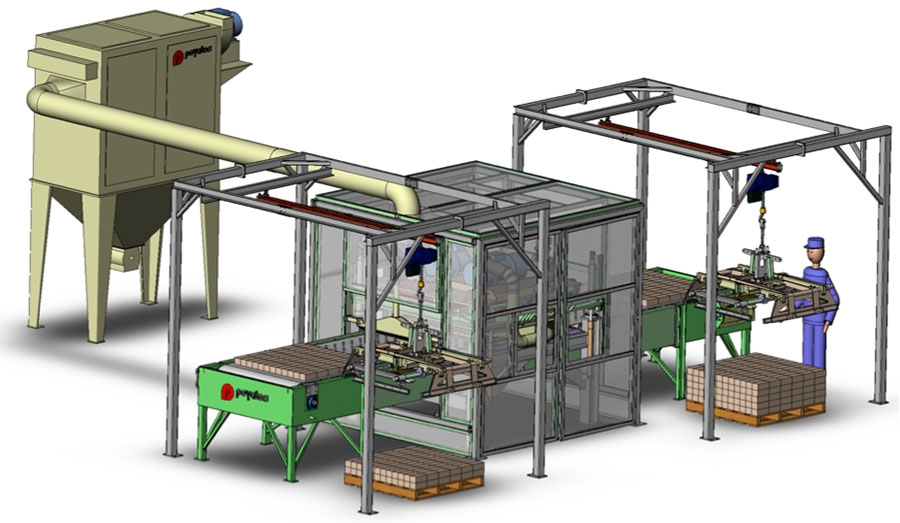

In this way, our range of machinery for surface treatment of precast concrete and for the special finishing of concrete blocks includes: splitting machines, aging machines for finishing paving stones, shot blasting machines and bush hammering machines, color dosing systems, ColorMix systems for color gradient effect etc.

.jpg)

At this point, we will delve into 4 different types of machines:

1. Splitting machines for concrete blocks

The semi-automatic splitter for cutting concrete blocks comes equipped with 4 blades (inside, top and sides). And it has semi-automatic operation, with power from the hydraulic group motor: 7.5 HP.

Among the main technical characteristics of this machinery we find:

- Semi-automatic operation.

- Equipped with blades and support for blocks from 40 to 270 mm high (optional up to 420 mm).

- 600 mm long blades (optional up to 800 mm).

- Hydraulic group motor power: 7.5 HP.

- Hydraulic pressure: 115 Kg/cm2.

- Cutting force: 17,500 Kg.

We leave you the video with how it works and here you can download the pdf with all the information.

Automatic cleaver, Mod. A-600/4

We are talking about another model of this machine for special finishes of your concrete blocks.

- Automatic operation, equipped with 4 blades: upper, lower and lateral, with mechanically and hydraulically compensated efforts.

- Cutting length: 610 mm.

- Cutting height: from 40 to 270 mm (optional up to 370 mm).

- Hydraulic pressure: 115 Kg/cm2.

- Cutting force: 20,000 Kg.

- Production: 24 blocks per minute (12 cuts/minute) or 36 blocks per minute (18 cuts/minute).

We leave you the video with how it works and here you can download the pdf with all the information.

2. Aging process for paving stones

If you want to make your pavers look better, the aging-bushammer features a hammer aging procedure and is equipped with 144 hardened steel hammers.

In addition, it has a cabin to dampen noise and, at the same time, works as a dust suction chamber.

Among the main characteristics of the concrete block ageer we find:

- Patented aging machine for paving stones and other pieces on the top of them.

- Hammering aging procedure.

- Equipped with 144 tempered steel hammers.

- Optional: 144 bush hammer plates (not included).

- Power: 6 kW.

- Equipped with a cabin to dampen noise and, at the same time, act as a dust suction chamber.

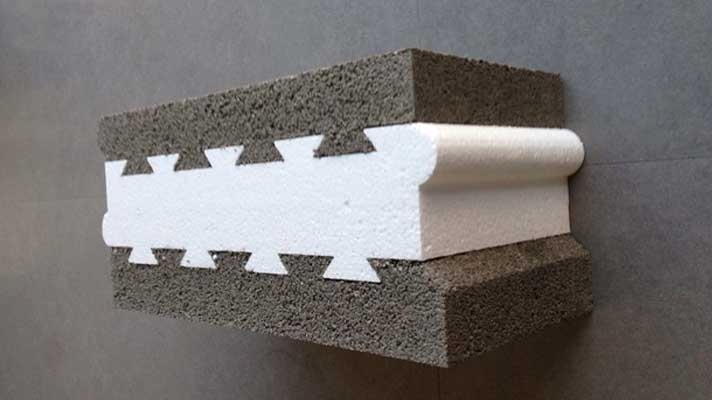

3. Polystyrene injection systems

Other machines that will help you offer a better finish for concrete blocks are systems for inserting polystyrene sheets. At Poyatos you can find systems for inserting patented polystyrene sheets for the manufacture of insulated blocks, in all block maker models. Automatic or manual execution depends on the model.

4. Color dispensing systems

Finally, at Poyatos you will also find the dosing and color distribution systems for granular powder dyes for all block machine models. Our range of machinery for prefabricated surface treatment and special finishing includes color dosing systems, ColorMix systems for the color gradient effect, etc.

Get better finishes on concrete products by inserting polystyrene sheets and with color.