Do you want to know what concrete plants are and how they work?

Then this article will interest you, we tell you a little about this type of facility and we delve into our machinery for concrete plants.

We start first with a brief description that we can find on Wikipedia, where we can read:

A concrete plant is a facility used to manufacture concrete from the raw material that composes it: aggregate (sand and gravel), cement and water (it can also include other components such as filler, reinforcing fibers or additives).

These components, which are previously stored in the concrete plant, are dosed in the appropriate proportions, to be mixed in the case of mixing plants or directly unloaded into a truck mixer in the case of dosing plants.

Types of Facilities

On the other hand, it should be noted that there are various types of facilities. In this way, we find the following classifications:

- The concrete that is produced: Mixing facilities (mixed concrete), Batching Plants (mixed concrete), Gravel-cement Plants (semi-dry mixture of gravel with cement) and Combined Plants (mixed and dosed concrete in the same plant).

- According to the mobility of the plant we find: Fixed plants (facilities destined to a fixed production center), Mobile plants (facilities for a specific work or project), and Modular plants (intended to work in several different locations in their useful life).

- Based on the aggregate collection system Vertical floors (according to what we read on Wikipedia: "the collection of aggregates is carried out in the upper part of the plant, so they must be raised prior to storage") and Horizontal plants (”The collection of aggregates is carried out at ground level, and not on the level of mixing/dosing of the plant”).

.jpg)

Concrete Plants in Poyatos

We now enter the Poyatos block making factory and we show you the different concrete machines that we have for your Concrete Plants:

a) Turbomixer

Thanks to the Turbomixers, we can achieve the complete process to manufacture concrete blocks. We can read on our website:

The Turbomixer has a manual and automatic drive, through a pneumatic or hydraulic system. It adapts to the types of block machines.

Operation of the Turbomixer:

We share the main characteristics of this machinery for concrete plants:

- The concrete mixer tank is fully lined on the bottom and sides with special bolt-on and replaceable anti-abrasive sheet steel plates.

- The arms of the blades are mounted in an articulated manner and cushioned by hard rubber silent-blocks, they are self-adjusting and replaceable, easily accessible and totally protected against dust.

- The pulleys are NI-HARD anti-abrasive. While the circular discharge gate at the bottom, made entirely of electro-welded steel, is mechanized and mounted on bearings. This allows a smooth drive with little effort.

- The drive can be manual and automatic, by means of a pneumatic or hydraulic system. Being able to carry from one to three discharge gates.

- The mixer is fully equipped with a removable cover provided with a registration hatch.

- The motor is fully accessible on the outside of the mixer.

Below we show you a table with the capacities and in this link you can download all the information:

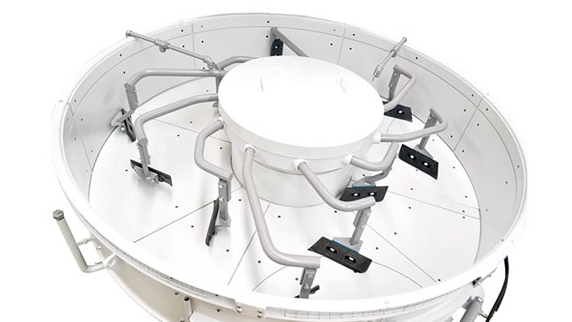

b) Planetary for concrete plants

Operation of the Planetary

Get faster production processes for your block machines. And we are talking about a concrete that is:

State-of-the-art machinery for your plants with a mixer turbine with planetary movement and a group of turbo blades. With it you will ensure a faster block production process.

Among its main characteristics, we find:

- Replaceable and cushioned blades.

- Unloading by means of a circular hatch at the bottom with a hydraulic drive.

- Protection with anti-abrasive wear plate on the bottom and sides.

- Prepared to install automatic humidity measurement and cleaning equipment.

Download the complete catalog here, and find out the capacities in the following table: