Know the automatic palletizing systems?

In this article we want to define a little deeper into the subject and for this we will start with a small definition. To later talk about the types and end with an explanation of the automatic palletizing systems in Poyatos.

In this way, we can start by saying that automatic palletizing solutions will allow us to manipulate the products in layers or unit loads for different product formats (we talk about bags, containers, boxes, etc.). An action that will help us achieve greater productions and improvements in working conditions (automating the most expensive and heavy tasks); as well as a significant cost reduction.

Automatic palletizing systems using robots

To talk about this topic, lets refer to Wikipedia, where we find:

The interaction, modification or termination of products in the final part of their production process is considered end of line. After the production of a product, it must be commercialized and distributed. Today the dimensions and weights have been standardized once the product has been finished and packaged, in order to facilitate its transport and storage, in addition to homogenizing its treatment and reducing production, distribution or logistics costs.

Wikipedia

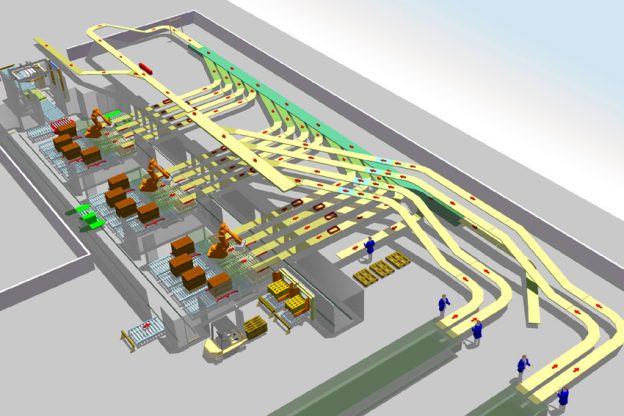

In this environment, automatic palletizing systems using robots arise, which are used for automatic palletizing in those productions with high cadences or when working conditions, ergonomics, product weight, environmental or hygiene conditions, require that the work not be performed directly with the manipulation or intervention of man. The implementation of an automatic palletizing system carries out the engineering of the product, final pallet, production and logistics processes, as well as studying that the installation of a robot and accessory conveyors is an amortizable investment in relation to the realization of manual palletizing.

Wikipedia

Considerations to take into accountDepending on the number of units produced and the number of references, we can talk about various systems. Among the most innovative are multi-reference palletizers,

“which develop palletizing regardless of the morphology of the products, being able to palletize products with high slenderness, such as bottles. On the other hand, the system of taking of the products is decisive, since a take of the individual product or of several products, or of the complete layer, will determine the final cadence of the automatic palletizing system ”

Wikipedia

Considerations to take into account

When working with these types of systems, we must take into account some important aspects such as:

- 1. Articulated robots are more suitable when handling a smaller number of references, and in a smaller space than those of the gantry type. In addition, in this type of robots, “the configuration of the pallets develops around the robot, not being linear as in the portico. The cadence reached with an anthropomorphic robot is usually greater, since the routes are smaller and more optimized. ”

- 2. Gantry robots: they offer linear movement in 3 axes, “which allows for a greater number of in-line palletizing stations.” Therefore, “more references can be palletized for the same space and modernly with a single robot. "

- 3. As for the robot clamp we have to emphasize that there are several configurations and that these depend on several factors. Now, in general, we can talk about the following tapping systems: Blade clamp, Vacuum suction cups, Claw clamp, Mixed clamps.

Automatic palletizing systems in Poyatos

In Poyatos we design robots for special palletizing processes. And we integrate in our facilities robots with tweezers and programming designed and manufactured by ourselves for special palletizing processes. Robots are programmed and communicated to measure with the rest of the automation.