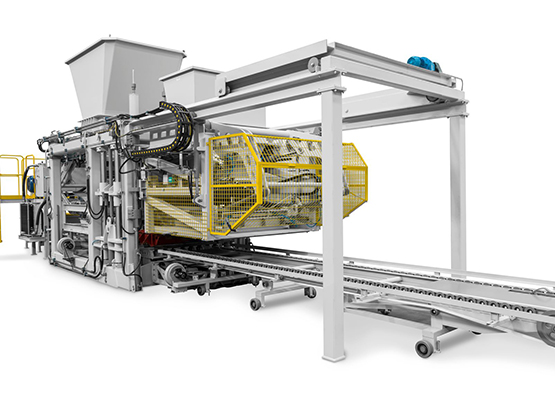

Are you looking for a concrete block machines with a reliable and experienced system?

Then Megabloc concrete block machines will become your best solution. These not only offer a reliable and experienced system, but also a tele-assistance service for breakdowns. In addition, they are the block machines with the highest production capacity.

We are talking about high production block manufacturing machines ideal for companies that require high production of concrete blocks. A type of concrete block machines that stand out for offering the highest productivity.

All of them, thanks to its vibration system with servomotors based on 2 independent vibration tables. Which allows filling compensation through independent regulation of the vibration parameters of each of the tables.

Modular Vibrating Block Making Machines

The Megabloc block maker features modular vibration, a system patented by Poyatos that consists of two vibrating axes synchronized unidirectionally. Each of them carries, at the same time, two eccentric masses that, at full load and at speed, without stopping, add or compensate, managing to vibrate or not, with the engine always running.

As we can read on our website:

The vibration system is made up of two vibrating tables with eight eccentric masses (four for each table), each one driven by a servomotor that allows controlling all the vibration parameters: frequency, amplitude, speed of phase changes, etc.

How does this modular vibration work?

The system that Megabloc concrete block machine have has several benefits, among which we highlight:

- Energy savings when starting and braking.

- Time savings in starts and stops (about two seconds per cycle).

- It ensures that there is no disintegration of material, as the vibration stops instantly.

Characteristics of Megabloc block machines

Finally, we would like to mention some of the specific features of the product; as they are:

- Different systems for the output of the finished product.

- It has a 12 tm multifork. Optional 180º rotation.

- It has control of the installation through a computerized control desk with touch screen.

- It offers production with 200x200x400mm blocks (blocks/hour). And/or production with rectangular paving 198x98x (60/80)mm (in m²).

- As an option, 90kW can be installed to manufacture with a second layer.

And, in addition, there is the possibility of MEGABLOC with one or two layers of concrete and single or double tray.

- To transport trays to the dryers, Megabloc block making machines are offered with an automatic multi-fork carriage, adapted to the characteristics of each project.

- The Megabloc block maker includes an electronic automatic palletizer with a double central column with translation and high-speed up and down movements with closed-loop control.

The Megabloc block maker is offered to work with wooden, plastic or metal trays.

Specific software with an easy-to-use touch screen provides all types of information on production, consumption, maintenance, etc. and allows a tele-assistance service with remote access.

You can get all the information in this pdf.