.png?width=770&height=404&quality=100&fit=bounds&dpr=1)

Do you want to know more about make concrete blocks?

Make concrete blocks is a complex process that requires precision, efficiency, and the right tools. With advancements in technology, the production has become more sophisticated, enabling higher quality and faster production rates.

Companies like Poyatos have been at the forefront of innovating and supplying machinery that significantly contributes to the concrete block manufacturing industry.

The Role of Advanced Machinery in Concrete Block Manufacturing:

The process to make Concrete block has evolved from manual methods to highly automated processes. This transformation is largely due to the introduction of advanced machinery that automates several stages of the production process, ensuring consistency, quality, and efficiency.

The main Tools and Machinery Used in Concrete Block Manufacturing:

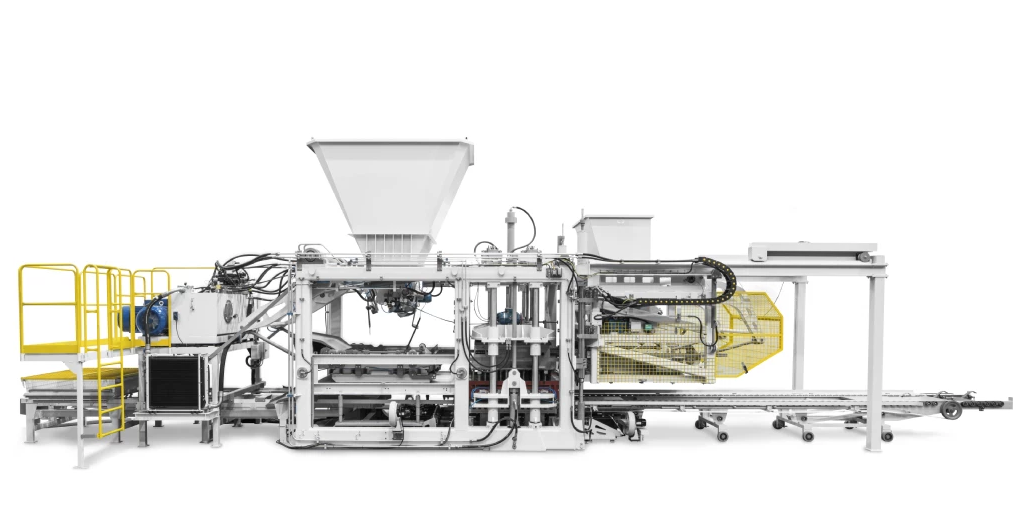

1. Block Making Machines

These are the cornerstone of any concrete block production plant. High-production machines, like those offered by Poyatos, can produce a vast range of blocks, bricks, and paving stones. Features to look for include versatility in the types of blocks produced, energy efficiency, and the ability to offer high output without compromising quality.

2. Batching Plants:

Precision in mixing concrete is vital for the quality of the final product. Batching plants ensure that the right proportions of raw materials are mixed together. Automated systems can control the exact amount of each material, leading to a consistent mix and, consequently, uniform blocks.

3. Molds:

Molds determine the shape, size, and texture of the concrete block. High-quality molds are essential for producing blocks that meet specific standards and requirements. Durability and ease of use are crucial factors in selecting the right molds for block production.

4. Curing Systems:

Once the blocks are formed, they need to be cured to achieve the required strength and durability. Modern curing systems control the temperature and humidity to ensure optimal curing conditions, enhancing the quality of the blocks.

5. Packaging Systems:

After curing, blocks must be packaged for storage or shipment. Automated packaging systems streamline this process, reducing labor costs and minimizing the risk of damage to the finished products.

6. Quality Control and Testing Equipment:

Quality control is integral to the manufacturing process. Equipment for testing the strength, density, and other properties of the blocks ensures that they meet industry standards and regulations.

The Importance of Customized Solutions

Every concrete block manufacturing plant has unique needs based on its production goals, available space, and the specific types of blocks it produces. Customized solutions, which include the design and layout of machinery and equipment to fit specific requirements, are crucial for optimizing production efficiency and product quality.

Choosing the Right Supplier

Selecting the right machinery and equipment supplier is critical. Look for companies with a strong reputation in the industry, like Poyatos, known for their reliability, innovation, and comprehensive customer service, including after-sales support and access to spare parts.

.png)

Conclusions about make concrete blocks

The industry that make concrete blocks is a significant industry that contributes to construction worldwide. The use of specialized tools and machinery has revolutionized this field, allowing for the efficient production of high-quality blocks. As technology continues to evolve, so too will the capabilities and efficiency of concrete block manufacturing.

Companies that invest in the latest machinery and opt for customized solutions from reputable suppliers like Poyatos will remain competitive and succeed in meeting the growing demands of the construction industry.