Do you want to know more about types of automation in the industry?

Over the last few decades, there has been a rise and increase in the use of various forms of manufacturing automation. It was originally used as a manufacturing technique after World War II, and by the 1970s, it had become standard practice in the industrial sector. So, today we go to talk about types of automation in the industry.

The term "manufacturing automation" refers to a methodology used in manufacturing that relies on electronic devices to streamline and speed up various stages of the manufacturing process. Its purpose is to boost manufacturing output more quickly and effectively than was previously possible by human labour.

Automating processes allows factories to produce more while employing fewer workers on the assembly line and more in other roles such as system design, management, supervision, installation, and troubleshooting. To maintain the same level of productivity, higher levels of skill are now required in the industrial sector, changing the nature of the work involved.

How many distinct types of automation are there?

Next we are going to talk about different types of automation in the industry:

1. Programmable Automation

With the help of programmable automation, assembly lines can adapt to numerous product variations with ease. Programmable automation is automation in which the sequence of actions is determined by a program, which takes the form of a collection of instructions that can be read by the system and followed to complete the desired tasks. Batch production can greatly benefit from this automated system"s adaptability to changing product configurations.

2. Flexible Automation

Because of this automation, the system can switch from one task to another without wasting time. The adaptable machinery allows the mass production of a wide range of goods. Rapid reprogramming and physical configuration changes will enable the system to manufacture a variety of goods in a short amount of time. A system like this may adapt to a wide variety of situations Manufacturing diverse mixtures of products is possible, there will be minimal production rates, and there will be variety in the soft items available.

3. Fixed Automation

Fixed automation systems, also known as hard automation, are used to perform a constant series of actions. Due to its purpose, this system is frequently implemented in continuous flow and discrete mass production setups. An automated conveyer belt system is stationary automation equipment that helps get things from A to B quickly and easily. Like other components of fixed automation systems, automated conveyer belts carry out routine tasks to maximize output.

Adopting a fixed automation system, such as automated conveyer belts, and integrating value-added solutions to save both time and labour costs in their installation relieves competitive pressure on your firm, boosts your profit margin, and keeps you ahead of the competition. Using bundled wire for automated conveyer systems illustrates a value-added solution. This speeds up the installation process, saves labour money, and prevents workers from getting hurt while pulling wire.

4. ntegrated Automation

Manufacturing facilities are fully automated in an integrated automation system, with minimal human intervention. Computers can create blueprints, run simulations, and build components. In the same way that flexible automation can be used with either batch or continuous processes, integrated automation can also be.

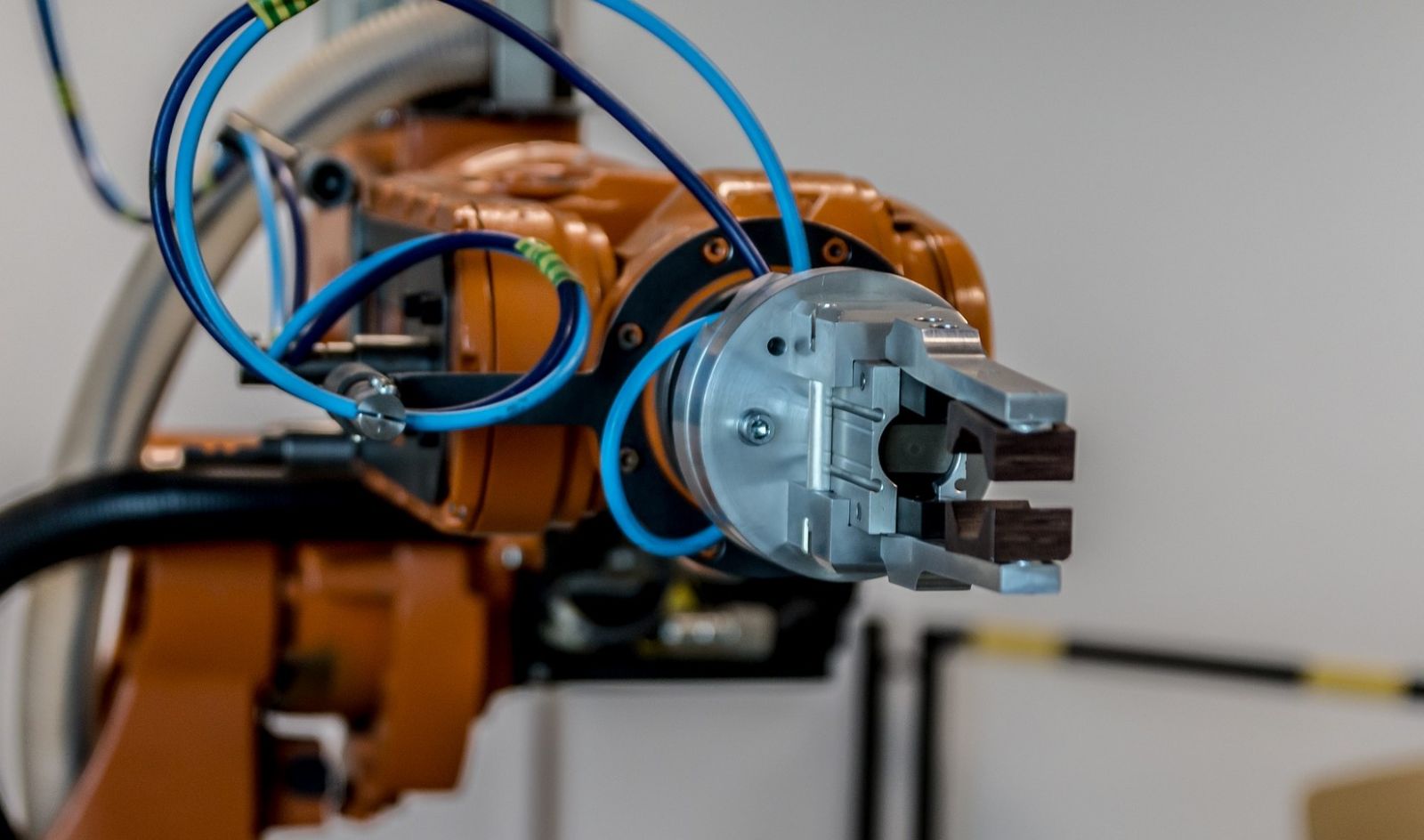

Automatic storage and retrieval systems, flexible machine systems, automated material handling systems like robots, computer-aided process planning, computer-supported design and manufacturing, computer numerical control machine tools, computerized production and scheduling control, automatic archival and retrieval techniques, and automated conveyor belts and cranes are all examples of technologies that use any types of automation.

Conclusions about types of automation in the industry

Factors such as labour circumstances, competitive pressure, production and assembly specifications, job requirements, and the cost of labour should be considered when deciding on the appropriate level of industrial automation for your manufacturing plant. If you think these, you can rest assured that your investment in industrial software automation will be well-justified by a steady rise in profits.