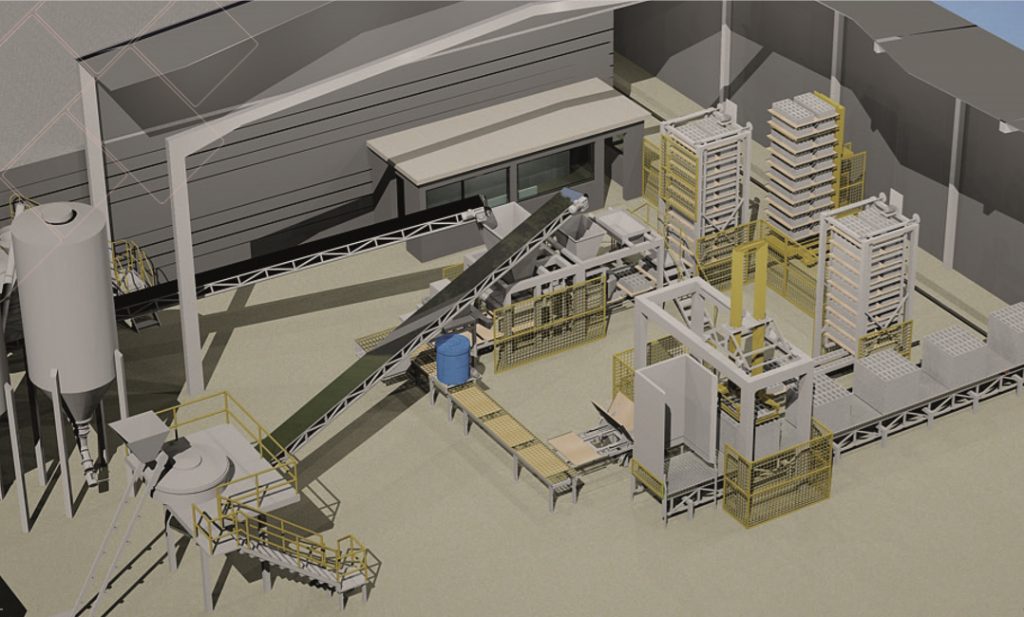

Are you an entrepreneur? The Prima economical block machine will adapt to your needs

We are talking about the most economical block machine; It is ideal for manufacturing quality blocks, both at an industrial level and for manufacturing special parts. And, in addition, it also adapts to the needs or context of entrepreneurs who are going to launch a project in a developing country.

This model is made up of fixed presses that have a high production capacity. Both for the production of concrete and the manufacturing of parts automatically. A block machine that is also characterized by its robustness and its ease of use and maintenance.

And furthermore, it does not require large installations to make the block making machine (15.75 KW) functional. Something that becomes a great advantage, both functionally and economically; especially for developing countries in which electrical installations do not yet offer great functionalities.

Prima economical block machine operation

The Prima block maker goes one step further than laying machines, and becomes a semi-automatic process. And, instead of the machine moving (taking up excessive space), it is the trays themselves that do it.

And once the pieces are vibrated on wooden or metal trays, they are removed by an operator, with a cart, to transport them to the curing area. Subsequently, the pieces will be palletized manually. It is therefore a semi-automatic process that allows a much higher production than laying machines. On our website you can find out all the technical characteristics of the Prima economical block machine:

As we can read on our website:

In these block machines, once the concrete products are manufactured on the production trays, they are removed by an operator with the help of a cart and transported to the curing area. Subsequently, the products will be palletized manually. They have metal or wooden trays.

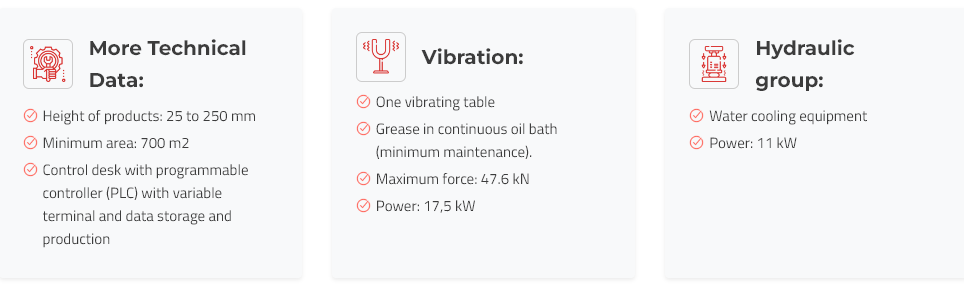

Main technical data of the Concrete block making machines

Regarding the technical data, it should be noted that it has a control desk with a programmable controller (PLC), with a variable terminal and data and production memorization.

In addition, the Prima block machine has a vibration table with a power of 17.5 kW, and a hydraulic group with 11 kW power.

Prima L: a more automated and dynamic block machine

If you want to go one step further, but continuing with the idea of looking for economical block machine, the Prima L is an ideal version for you. As we can read on our website:

PRIMA L, the most automated and dynamic version. It includes the same PRIMA block machine, but with a higher level of automation. In this installation, an elevator-descender assembly is added, which facilitates the process of transferring the trays for curing the products. It also includes a clamp for the final palletization of the pieces.

In Prima L block machines, by depending less on the human factor, production is streamlined and the productivity of the installation increases.