Do you want to know more about Maintenance and Care of Block Making Machines?

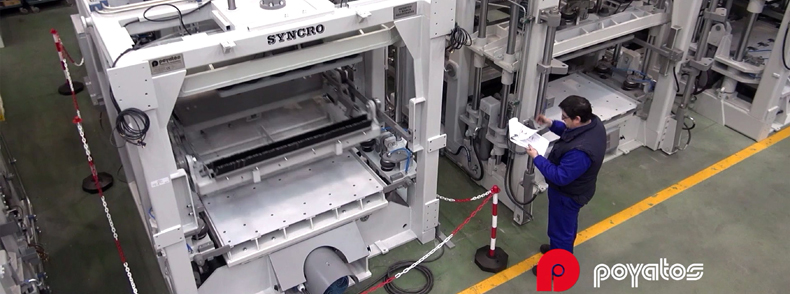

Concrete block Making Machines and other block-producing machines are gaining popularity in developed and developing nations due to their ability to produce blocks quickly, reliably, and robustly. These devices are highly efficient but require regular servicing to function properly.

These devices must operate in the harshest climates and environmental circumstances, including constant exposure to gravel, sand, and microparticles.

Due to the demanding conditions in which these concrete block manufacturers operate, routine maintenance is required to ensure peak performance and prolonged machine life.

Taking a few basic precautions can increase machinery"s useful life and improve its efficiency. Some things to think about before beginning maintenance are listed below.

- Abnormalities should never be ignored: When anomalies are identified, the machine must be turned off immediately to determine the cause. Even a minor problem, if left unattended, could cause the entire system to fail.

- Having qualified experts: Having someone without the necessary expertise do maintenance and servicing on the machinery is far more concerning. If a problem is ignored or not addressed, it can grow into a much bigger problem, so it"s important to have only trained professionals do maintenance and repairs.

.png)

Now that we have a general idea of how to maintain our equipment, we can move on to more specific measures to increase efficiency and extend their lifespan.

Controlled Evaluation of Progress

Each component of the block Making Machines should undergo routine performance inspections. The inspections should include testing all controls, switches, and other parts to ensure optimal performance. If an error is found, fixing it must be a top priority.

Before Powering On the Machine

Before starting the block-producing machine, it"s important to do a quick performance check to ensure everything is in good working order. Before putting the machine to use, it can be inspected for lubrication, performance anomalies, faulty parts, and loosening. In doing so, we can avoid a total system failure and a work stoppage.

Maintenance Schedules That Include Lubrication and Cleaning

Microdust is a common problem in block Making Machines , as it can impede the mechanical parts" ability to move and even prevent lubricant from flowing properly. Inadequate lubrication and microscopic particles, known as "microdust," are two of the most common causes of poor system performance. A machine"s wear and tear can be avoided by keeping it clean and well-lubricated regularly.

Repairs Needed Due to Cold Weather

The production of any heavy machinery is not the same in the winter as in the summer because of the vast differences in air conditions. Because of the prevalence of water consumption in production, materials may freeze if the temperature drops too low. Insulating raw materials and encouraging their use of antifreeze are two possible solutions. Since lubricants can potentially be damaged by freezing temperatures, it is recommended that antifreeze be included in them. It is recommended that all hydraulic fluids be drained from equipment before putting them to sleep.

When something breaks, replace it

Parts of frequently used machinery eventually wear down and must be replaced to ensure peak performance. Changing them out when worn out helps keep other components from getting worn out or damaged. Maintaining a modest supply of frequently used parts on hand is helpful to avoid equipment downtime.

Expert operators for the concrete block production equipment

Maintenance and servicing performed by an incompetent individual is far worse than no maintenance. When a little problem is ignored or improperly fixed, it can quickly escalate into a much larger one.

As a result, only trained technicians must execute maintenance and fixes. A block Making Machines reliability, efficiency, and longevity can all be improved by regular maintenance of its mechanical parts.

Conclusions about Maintenance and Care of Block Making Machines

Using the above measures, you may increase your Return on Investment and make the most of your costly machinery. You should follow this tips and keep your block machines always maintained.