Do you want to know more about concrete plants?

Before delving into knowing how a concrete plant works, it is essential to know the basics of building concrete plants. And it is that this type of machinery will mix different aggregates such as: sand, water, cement and additives.

In them, ready-mix concrete is prepared by separately weighing each of these ingredients. Several different types of construction projects benefit significantly from prepared material.

In this way, and since the proportions of the constituent ingredients are determined by weight, in concrete plants it is possible to make concrete of different qualities simply by adjusting the weight of the different components. People use a variety of mixes and grades of concrete, including (1:3:6), (1:2:4), (1:1:2), etc.

Specification of relative amounts of cement

Here is the specification of the relative amounts of cement, fine aggregate, and coarse aggregate used to make concrete. The ratio of cement to fine and coarse aggregates is defined by the notation "1:3:6". This means that there are three parts fines and six parts coarse aggregates in the mix. The proportion is based on the total weight.

Varieties of concrete batching plants

Concrete plant manufacturers have created a wide variety of models to meet a variety of requirements. These variants will help fill a wide range of needs.

Concrete plants can be divided into two categories:

- Dry concrete plant

- Wet concrete plant

Dry mix plants, as the name implies, prepare dry mixes before sending them to a transit mixer. The aggregate, sand and cement required for the job are measured and loaded into a transit mixer after weighing. The transit mixer is watered. Transit mixers are used to mix concrete on the way to the construction site.

Materials for wet mix machines are measured and weighed before being fed to a mixing unit, which then mixes the ingredients thoroughly before being sent to a transit mixer or pump unit.

This type of facility, also called a central mix plant, provides a more homogeneous final product because all materials are combined in one location with the aid of computers.

Concrete Plants Designs

When classifying the various layouts, there are two broad categories: stationary and mobile. Contractors that were not constantly moving their operations to new locations generally opt for stationary rates. Additionally, stationary mixers are often larger than their portable counterparts. Modern mobile batch plants are built to last and are just as reliable, prolific and precise as their stationary counterparts.

.png)

An inside look at how concrete plants work

A mobile concrete batch plant can be much smaller than a permanent one. It works similar to the smartphone version in most ways. Customers who want to produce concrete at a stationary location tend to prefer the stationary version, while customers who want to move locations frequently favor the portable version.

Essential functions

The five essential functions that make up the operating principle of concrete plants are the following:

- Feeding of aggregates and sand into separate feed bins is necessary for the production of aggregates.

- Cement, fly ash, and additives are examples of dust that can be fed to a plant during the dust feed process. These elements are crucial for any binding process.

- The ability of the cement to bind equally with the aggregates is greatly improved by adding water. Any prepared mix requires a certain amount of water to work.

- Included in this category is the transportation and storage of cement, fly ash, etc. They must store large quantities and move them in increments through screw conveyors to weigh bins.

- The control system is essential for any complex machine. Facilitates fast and precise work.

Feeding of aggregates into individual bins is the first step in the concrete batch plant process flow. Aggregates are separated by size and supplied in separate storage containers.

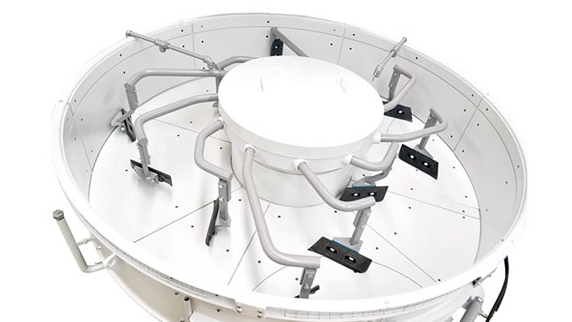

Each aggregate will be weighed separately according to the parameters established in the control panel. After being measured, they will be transferred to the blender. Above the mixer there are three weighing hoppers for the cement, the admixture and the water. The consideration hopper should measure the right amount of materials into the next mixing device.

A screw conveyor delivers cement to a weight hopper. The weighing hopper is filled with water by means of a pump. The contents of the mixer will be discharged into a transit mixer or concrete pump after the mixing period has elapsed.

Each step of the above procedures is done in a meticulous and well-organized manner. There is a time limit attached to each action. Batch time is the amount of time from when the aggregates are weighed to when the ready-mix material is discharged.

Conclusions about concrete plants

Finding the optimal balance between quality and cost is crucial when selecting a concrete plant; the machinery must be of a high standard but not break the bank.

Poyatos has become an industry leader due to its focus on satisfying its clientele. We can create innovative solutions that increase revenue by learning from our customers and incorporating their feedback into future product development.

We want to leave a lasting impression on our customers by delivering products and services that exceed their expectations and last for years. Our first goal when producing any item is to make the buyer happy.