.png?width=770&height=404&quality=100&fit=bounds&dpr=1)

Do you want to know Advantages of Using a Concrete Block Machine?

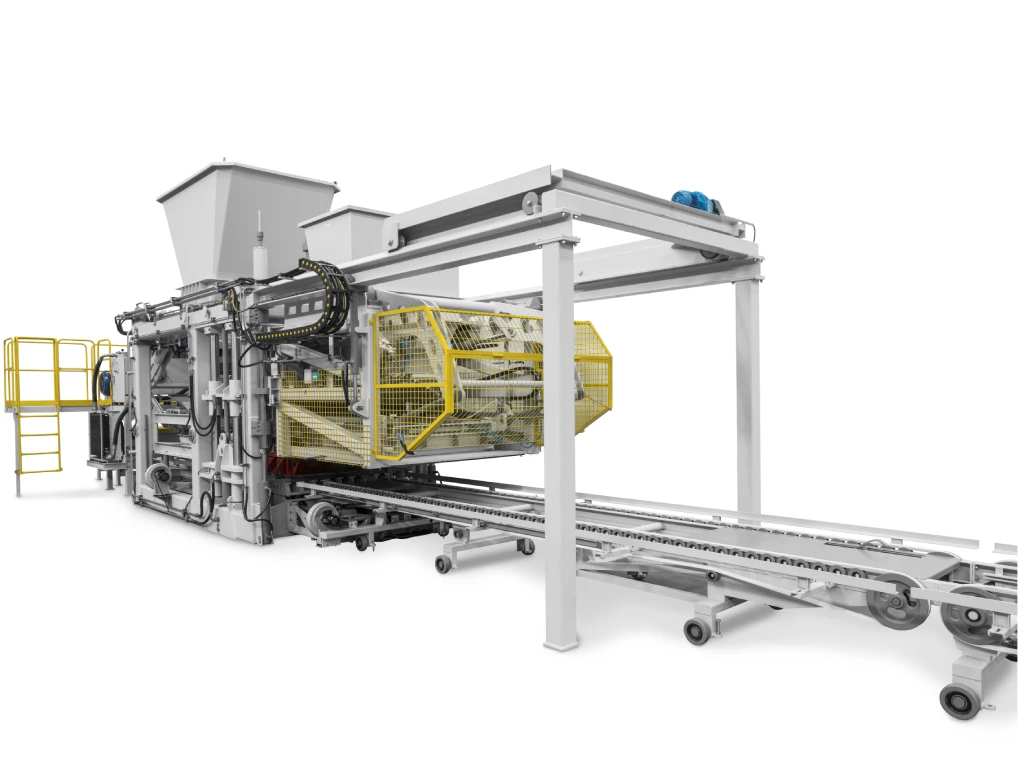

In the rapidly evolving construction industry, efficiency, sustainability, and quality stand out as paramount concerns. Concrete block machine have revolutionized how construction materials are produced, offering a myriad of advantages over traditional methods.

This blog post explores the multifaceted benefits of using concrete block machines for block production, underscoring why they are a cornerstone of modern construction projects.

.png)

1. Enhanced Efficiency and Productivity

One of the primary advantages of using a concrete block machine is the significant increase in efficiency and productivity it offers. Unlike manual production methods, which are labor-intensive and time-consuming, these machines streamline the manufacturing process, enabling the production of hundreds or even thousands of blocks per day. This efficiency not only meets the high demand in booming construction markets but also ensures timely project completion.

2. Consistency and Quality Assurance

Quality control is crucial in the construction industry, where the strength and durability of building materials cannot be compromised. Concrete block making machines are engineered to produce blocks of uniform size and shape, ensuring consistency across all units. This uniformity is vital for the structural integrity of construction projects and contributes to a professional finish.

3. Cost-Effectiveness

Investing in a concrete block machine can lead to substantial cost savings in the long run. The automation of block production reduces labor costs significantly. Additionally, the ability to produce large quantities of blocks on-demand minimizes waste and optimizes the use of materials, further driving down production costs. These savings can then be passed on to clients, enhancing the competitiveness of businesses in the construction sector.

4. Environmental Sustainability

Sustainability is a growing concern in the construction industry, with an increasing demand for eco-friendly practices and materials. Concrete block machines address this demand by enabling the use of recycled materials in block production. Moreover, the efficient use of resources and reduced waste contribute to a lower environmental footprint, aligning with global sustainability goals.

5. Versatility in Block Production

Modern concrete block making machines offer unparalleled versatility, capable of producing blocks of various sizes, shapes, and types to suit different construction needs. Whether it's standard blocks for building construction, interlocking blocks for paving, or specialized blocks for aesthetic purposes, these machines can be adjusted to produce a wide range of products. This versatility allows construction companies to cater to diverse project requirements with ease.

6. Automation and Ease of Use

The automation integrated into contemporary concrete block machine simplifies the production process, making it accessible to operators with minimal training. Advanced models feature user-friendly interfaces, self-diagnosing systems, and remote monitoring capabilities, ensuring smooth operation and easy troubleshooting. This ease of use enhances productivity and reduces the likelihood of errors during production.

7. Support for Local Production

Concrete block machines empower local production, reducing the need to import building materials. This not only supports local economies but also minimizes transportation costs and carbon emissions associated with long-distance shipping. Local production also enables quicker response times to market demands, offering a competitive edge in fast-paced construction environments.

8. Long-Term Durability and Low Maintenance

The blocks produced by these machines are known for their long-term durability, capable of withstanding harsh weather conditions, pests, and fire. This durability ensures the longevity of construction projects, minimizing the need for repairs and replacements. Additionally, concrete block machines themselves are designed for longevity and require minimal maintenance, ensuring reliable performance year after year.

Conclusions about Advantages of Using a Concrete Block Machine

The advantages of using a concrete block machine for block production are clear and multifaceted. From enhanced efficiency and productivity to cost savings, quality assurance, and environmental sustainability, these machines represent a critical investment for businesses in the construction industry. As technology advances, the potential of concrete block machines continues to expand, promising even greater benefits for construction projects worldwide.

Embracing the use of concrete block machines not only aligns with the modern demands of the construction industry but also positions businesses for future growth and success. By leveraging the power of innovation, companies can deliver high-quality, sustainable, and cost-effective solutions that meet the evolving needs of clients and the environment alike.