Do you want to know the latest news in construction? Today we talk about umbrella bridges and collapsible concrete

As we know, in recent years, technology has revolutionized the vast majority of business and industrial sectors, as well as our daily lives and society in general. Now, how has it influenced the world of construction? Well, about some of the last great revolutions we want to talk to you about today, and these are umbrella bridges and collapsible concrete.

But first, we want to highlight the importance of the advances that have been taking place in the construction sector. How the engineering and manufacturing systems have been perfecting the constructions, and have achieved the most advanced results.

But, now, we talk about the two aspects that concern us in this article, and for this we go to this article from El Español: From umbrella bridges to collapsible concrete: technological revolution in construction.

An umbrella bridge

The TU Wien Umbrella Bridge, one of the latest innovations in construction, and one that has revolutionised this world. As we can read in the article:

One of the latest innovations that has attracted the most attention is the construction of a deployable bridge that is brought to its final position with the same principle of opening an umbrella. The pioneering project has been carried out by the Technical University of Vienna applying it to a motorway in their country. The method was patented in 2006, although it was slow-moving until the first large-scale application in 2010.

The operation is simple and at the same time surprising. In the first step, the beams are mounted vertically on both sides of a concrete pillar that will serve as a connecting link when they are vertical.

Hydraulic system

In this way, a deployment is carried out through a hydraulic system, which is placed on the central scaffolding that gradually lowers the reinforced concrete beams. Some precast and hollow beams to reduce weight.

In the words of Johan Kollegger of the Institute for Structural Engineering at the University of Vienna:

"Erecting bridges with the traditional method can take months. Using the balanced reduction method (as it is technically called), they can be completed in two to three days, and the deployment process takes around three hours,

The ecological folding concrete

Another of the revolutions in the world of construction is ecological collapsible concrete, as we read in the article:

The manufacture of cement is a process that emits, through pure chemistry, tons of carbon dioxide into the atmosphere. In addition, the manufacture of clinker (raw material of what we know as cement) requires 1,500 degrees to form. The cement plants use petroleum coke and waste such as tires to feed the kiln that must work 24 hours a day, 7 days a week.

Swinburne University

And, one of the examples of this type of concrete, has been developed by the University of Swinburne in Australia, in order to avoid part of the emissions. In this way:

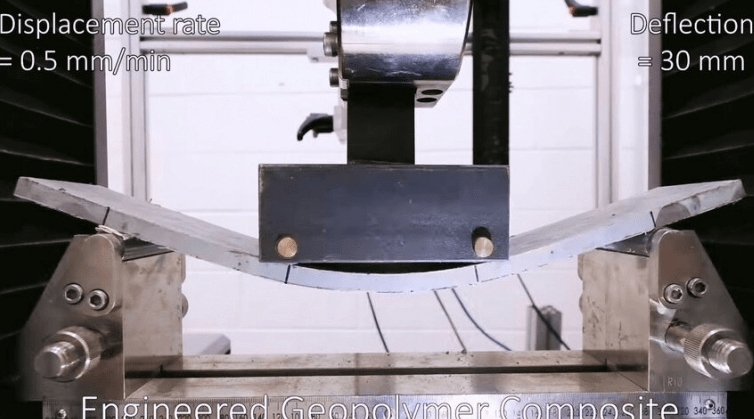

They have managed to develop a concrete that, in addition to being foldable, considerably reduces the carbon footprint. Bendable concrete has been studied and manufactured for decades but required exactly the same energy as their less flexible siblings.

The new formula created at the University of Swinburne forgets about cement for the manufacture of this type of concrete. Instead, it uses a geopolymer that manages to match the same properties of normal concrete, adding a tensile strength well above the average for traditional (unreinforced) concrete.

And, among the main benefits of this type of product (which we still do not know how long it will take to be used in construction) we find: energy savings of 36% in its production and the fact that it avoids emitting 76% of carbon dioxide compared to traditional cement manufacturing.