Are you looking for concrete block machines with maximum productivity?

Then we cannot offer you a better solution than our Megabloc concrete blocks machines, which offer a reliable and experienced system, with maximum productivity per hour.

The Megabloc model block amaking machines stand out for offering the highest productivity on the market (more than 4,500 20 cm blocks per hour, 18 pieces per tray) thanks to their modular vibration system (patented), powered by a single 45 kW motor, based on 2 independent vibration tables.

This allows a compensation of the filling through the independent regulation of the vibration parameters of each one of the tables.

In addition, the system includes an encoder to control electronically and with maximum precision the frequency and amplitude of the vibration.

Poyatos patented modular vibration

This type of concrete blocks machines have a modular vibration (Patented by POYATOS) consisting of two vibrating axes synchronized unidirectionally. And, as we can read on our website:

The vibration system is made up of two vibrating tables with eight eccentric masses (four for each table), each one driven by a servomotor that allows all the vibration parameters to be controlled: frequency, amplitude, speed of phase changes, etc.

We leave you a presentation video that you can find on our YouTube channel:

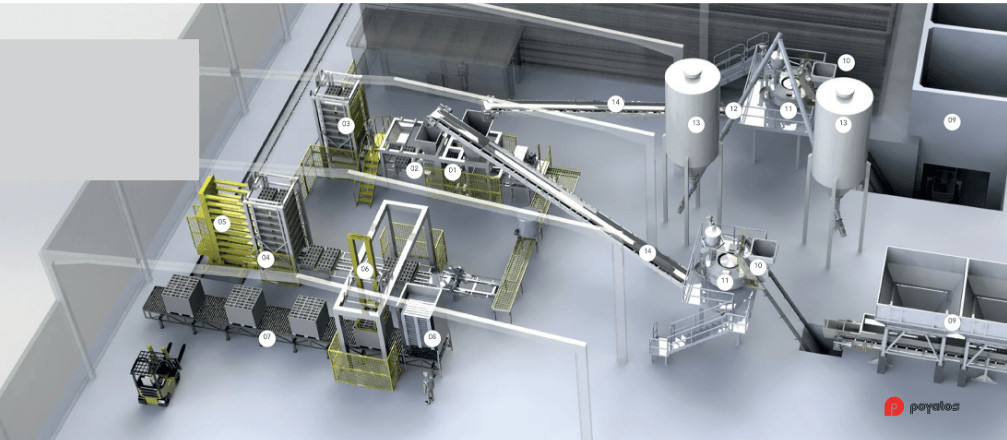

Main characteristics of the Megabloc block machines

Among the main particular characteristics of this type of concrete blocks machines we find:

- We highlight the Multiforce 12 tm. With the possibility of turning 180º.

- In addition, it has control of the installation through a computerized control desk with touch screen.

- Regarding production: we are talking about production with 200x200x400mm blocks (blocks/hour). And with a rectangular paver 198x98x(60/80)mm (in m²).

- Lastly, we can highlight the possibility of installing a 90kW facility to manufacture with a second layer.

In this other video you can learn more about how it works:

Automatic palletizer

It should also be noted that the Megabloc block making machine includes an automatic electronic palletiser with a double central column with translation and high-speed up and down movements with closed-loop control. That, as we can read on our website:

This allows for shorter operating times and reduced electrical consumption. Tightening is independent in both directions, with force regulation to apply the appropriate pressure parameters to each piece, memorized for each product in the installation program.

In addition, a wide variety of options are offered for the output of the product packages (roller conveyor, slat conveyor, pallet truck, etc.) according to the needs of each project.

Specific software

Finally, it should be noted that these block machines are equipped with an easy-to-use touch screen that provides all kinds of information on production, consumption, maintenance, etc. and allows a tele-assistance service with remote access.

Main advantages of modular vibration in Megabloc block machines

Having this type of block machines in your concrete plant will help you:

- Save time in starts and stops (about two seconds per cycle).

- To ensure that there is no disintegration of the material, since the stoppage of the vibration is instantaneous.