Do you want to know How Do You Work In A Concrete Block Machine?

The functioning to Concrete block machine depends on the concrete"s vibration and compression. They contain a hopper for receiving and storing the new cement needed to make the blocks. The substance is then dosed in to fill the mould to the proper levels.

The tray, the mould, and the shaker are all vibrated to make it simpler to fill each mould.

After completing this stage, the item is compacted to its final size, and any air pockets between the sand grains and the gravel are taken out. It then vibrates again to aid in compression (harder than when the mould was filled).

Let"s dig in and learn more about the functioning of the concrete block machine to help you with the best services.

What Is The Operation Of The Automatic Concrete Block Machines?

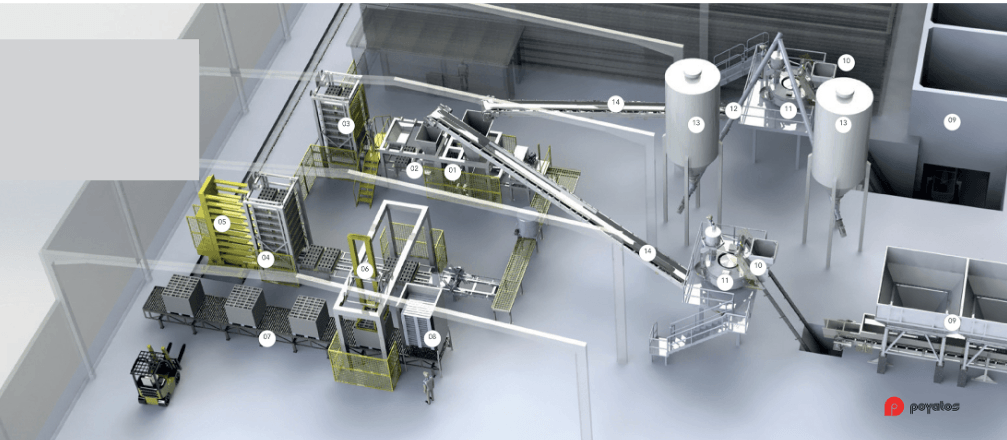

Among the numerous types of concrete block machines, there are many choices. For example, the machine may feature a pneumatic, automated palletizer, et cetera.

The vibrating table, the mould with various holes to modify the size and kind of concrete blocks that may be created, the compacting plates, etc., are some additional pieces or mechanisms that a concrete block making machine contains.

Elements of Concrete Block Machine Equipment That Are Beneficial

The main qualities of a block making machine are listed below, and they help construction organizations fulfil deadlines while still producing high-quality work.

Blocks of Superior Quality

The concrete block quality is the feature that people like about block-producing machines the most. Modern technology is frequently used in constructing this equipment, also known as a masonry unit-producing machine.

A raw material combination, such as concrete or slag, is conveyed to the mould box when it is poured into the distributor, a machine component. Then, the mould box is put under intense pressure. Concrete blocks made as a consequence are consistently formed.

Concrete block machine: Solution for Cheap Construction

Lower cost is another benefit of a block making machine over a manual brick-making procedure. You will need to spend much labour using a manual block machine.

However, the demand for the workforce will be drastically decreased in the event of automatic block making machines devices.

Simple Customization

It makes sense that block size and form specifications closely match those for the project. For instance, some projects may call for blocks of size X, and others may call for blocks of size Y.

Fortunately, a block-forming machine can help you satisfy all of these diverse consumer demands since it lets you alter the block sizes.

Most automatic block making machines include a sophisticated control system that enables you to alter the blocks" size and form to your preferences. This benefit allows you to manage your clients more effectively and sign new contracts without worrying about their block needs.

Shape Consistency

Precision, quality, and uniformity are essential benefits of block-forming machines in construction, along with a greater production rate. Additionally, once you"ve modified the mould to your preferred block size and form, you won"t need to worry about the items.

Ensuring the concrete block machine has an adequate supply of raw materials would be your primary concern. The device will continue to create blocks of the finest quality and in the correct size and form as long as it has a sufficient supply of raw materials and working parts.

Conclusion about Concrete Block Machines

Most of the time, the machine creates blocks of the most excellent quality; waste will be minimal. In addition, the machine creates blocks far more quickly than people can. This can help you save time and complete the job on time or even earlier than expected.

You"ll eventually be able to sign more projects and make more money. Automatic block making machines is a cheap option due to these elements working together.