Do you want to know about industrial robotics?

Industrial robotics can be referred to as robotic arms which have sensors, and controllers that can perform various functions and operations in the manufacturing of producers in industries. They are programmed to operate repetitively in cycles.

These robots significantly reduce the human factors involved in the production and also increase processing speed, quality as well as the capacity of production.

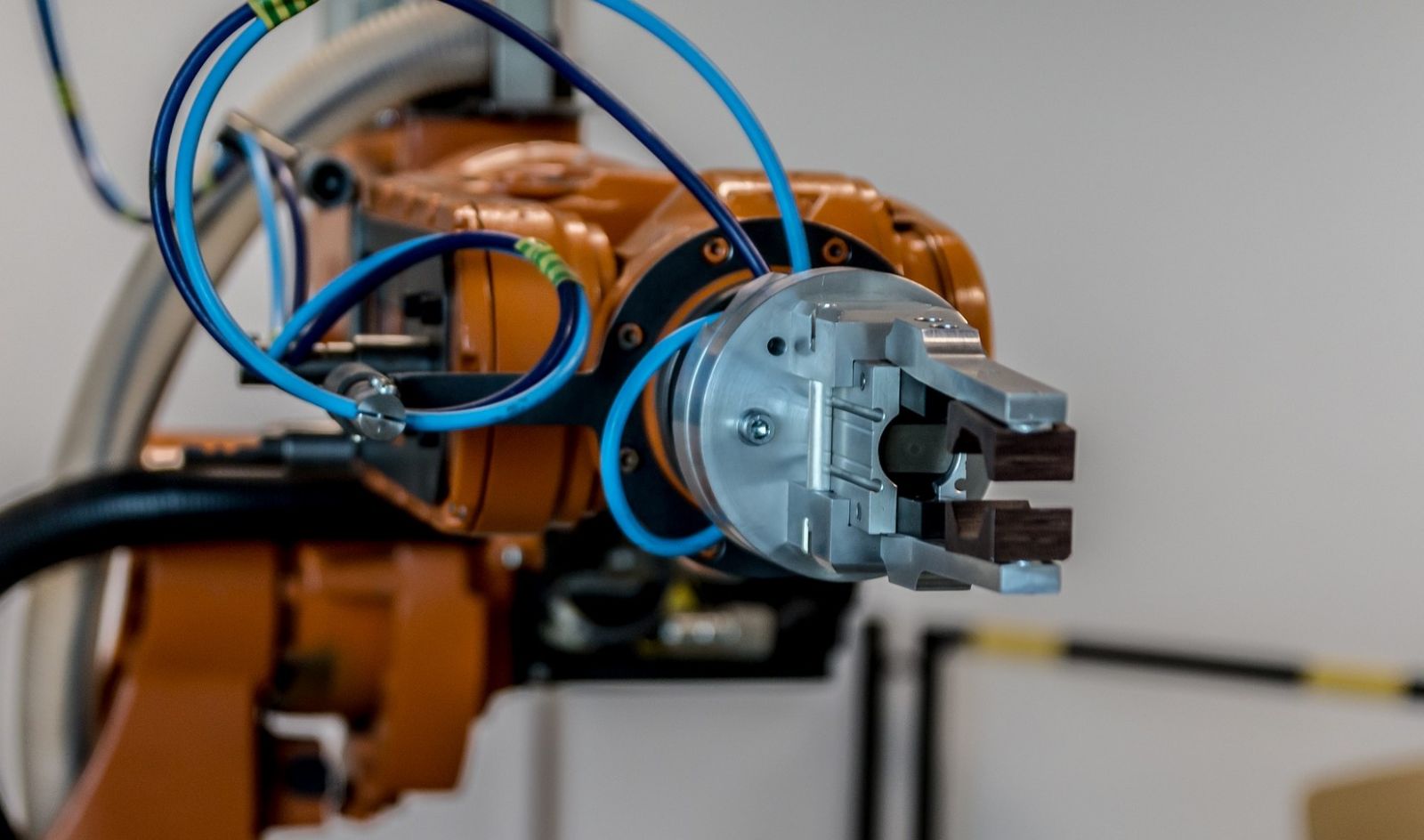

The most important part of the robot is obviously the arm which is made of joints and links. The end of the arm tool (EOAT) is the most important part of the robotic arm. They perform numerous functions like marking, cutting, welding, drilling, painting as well as cleaning.

Applications of industrial robotics

Robots are most commonly used for simple pick and place operations. However, with better sensors and control technologies they can be made to perform even more versatile functions.

Some applications of industrial robotics are given below:

1. Assembling products

Repetitive tasks like assembling products can prove to be tedious for humans. Hence, industrial robots are more suitable for this task as they are programmed to do repetitive chores.

This is why a huge number of industries use robots as assembly machines. To perform this task the EOAT is modified to mechanical grippers that are used to pick or place large or small material in quick successions.

2. Welding

These robotic machines are prominently seen in automotive industries. However, they are also used significantly in metal fabrication processes as well. Their robotic arms provide better and more precise welding.

This is because they have better control of parameters like arc length, current, voltage, weld rate and many others.

3. Painting

It is irrefutable that painting and coating require a high level of precision to achieve a layer of uniform thickness. Besides, this painting also involves exposure to some hazardous chemicals which can prove to be fatal to human beings.

Some pigments are even poisonous and have explosive properties aswell. However, all these dangers can be reduced by using robots for the job of painting and coating as it will remarkably decrease the human factors involved in the process.

.png)

Advantages of industrial robots

Initially, you may have to make a huge investment in order to install these robots in the industry. However, the numerous benefits of these robots will help you to get back your investment in just a matter of one to two years. So, let us know what are the benefits of industrial robots.

1. Increased rate of production

Unlike humans, robots are programmed to perform a repetitive tasks continuously without getting fatigued. This increases the working time in the industry and directly impacts the rate of production. In fact, if these robots are designed and maintained properly they can even reduce the production time which will again notably increase the production rate.

2. High load capacity

The actuators in industrial robotics are extremely strong as compared to humans. This is because they have a mechanical advantage due to specifically design configuration of the arms. This allows them to lift heavy objects more easily and efficiently.

3. Lower cost of operations

Since the use of robots decreases the overall need for manpower, this significantly reduces the cost of operations. Besides, the profit also increases due to the improved quality of products as well as the increase in the rate of production. Moreover, the efficiency of these robots also decreases the wastage of raw material which also adds to the economic benefit.

Conclusion about industrial robots

It cannot be doubted that robots are the future of industrial manufacture. This is because of the numerous benefits they provide. The use of robots has also made it easy to perform many functions and also increase the efficiency of all the processes involved in production. Hence, they are notably replacing humans in industries and helping to create major profits for the industries.