Do you want to know the main pathologies of Concrete?

In today"s article we will tell you about the main pathologies of concrete. To do this, we will resort to an on-line article as a source of information

As we know, concrete has become key in the construction sector due to its strength and resistance. It is able to make the most resistant constructions. However, there are also concrete pathologies that can affect its quality and durability, due to different causes (humidity, temperature, pressure...)

As we can well read in the article from Concrete On-line:

Timely diagnosis and repair avoids costly investments in the future, apart from the catastrophic consequences that a building affected by the most common concrete pathologies can cause...

What problems can appear in concrete?

Different concrete pathologies appear, such as ”environmental agents that reduce its strength, appearance and resistance over time”. Among them, we highlight:

Carbonation

Here we are talking about a natural phenomenon of concrete ageing. Under good and healthy conditions, the material has a basic pH of 13. However, the pH gradually drops to 9 when concrete reacts with CO2.

In this case, when carbonation appears, we find that the reinforcements in the structure corrode when the carbonate zone reaches them. They gain volume, which causes the concrete to burst, exposing cracks. Although this process can take years, when it occurs it is devastating and expensive to repair.

To check this variable of concrete pathologies there are several simple tests such as: Scrape a small area of the structure, preferably on the edges and clear it of the dust; then spray a mixture of phenolphthalein in alcohol and healthy areas will turn pink, but the carbonated areas will not change colour. This test has become routine in examining the carbonation status of buildings and concrete works.

Cracks in reinforced concrete

We are facing one of the most common phenomena in the life of a structure: concrete cracking, a defect that separates the material on a certain surface.

When can cracks occur? Well, when the concrete is: subject to tensile forces or designed without respecting the rules of solidity; when there is excess water in the mix” or the drying has been quick; also in various weather conditions, due to vibration or when there are no expansion joints.

And, although we are talking about a normal phenomenon, if measures are not taken, it can spread and cause the material to brea”.

Aluminosis

This is one of the most serious concrete pathologies, and it comes from the manufacture of concrete with aluminous cement. This was a highly sought-after material for the speed with which it set; however, its use is now prohibited. But there are structures made with this material.

To which they add:

The problem is that concrete is porous, losing its strength and capacity to resist weight. The first signs of aluminosis are yellow spots on the structure, the appearance of cracks or lack of adherence.

Aggregate alkali reaction

In this case, a kind of gel is produced that results in an increase in volume when it comes into contact with water. Creating breaks or fissures in the structure. This gel is the result of the alkaline emulsion that accumulates in the pores of the structure, together with the siliceous minerals of the aggregates.

Sulphate ion in the form of complex salts:

Among the pathologies of concrete are those produced by sulphate salts naturally contained in soils and waters. The intensity of the attack will depend on the amounts of salts, the permeability of the concrete, the amount of water in the subsoil, and the composition of the cement used.

What consequences can the different pathologies of concrete bring?

Having studied different pathologies, we would like to emphasise the consequences that these can bring, and we find:

- Costly repairs or demolition of parts of the structure: depending on the importance and correspondence with the rest of the building.

- Compromised building stability: it is true that cracks begin with very fine lines on the outside of the surface, however, if they are not treated in time, they can end up becoming large gaps that compromise the building’s stability.

- Structural calculation errors: that do not correspond to the load that the structure must bear, which ends up collapsing and putting habitability at risk. There are consequences due to errors in the performance of the work and different settling.

In short, the consequences can be very serious in economic, social and legal terms. Risk levels have been determined in building façades: the first level is the aesthetic part without major risks and easy to repair; the second corresponds to problems that can have significant consequences in terms of health and habitability, but without compromising the stability. If the building reaches the third level, it puts its inhabitants at risk and urgently requires rehabilitation.

What measures can we take to prevent these situations in our concrete blocks?

And, now that we know the serious consequences that it can bring, let"s see how we can prevent these situations:

- Avoid adding too much water to the mix. Since an excess of water will seriously affect the quality of the concrete

- Install the expansion joints. These allow the concrete slabs to contract and expand without breaking. The role of the joints is to absorb the expansion of the concrete under the effect of changes in the weather (cold, heat, wind) and soil pressure.

- Cure the concrete. It will prevent the water from evaporating too quickly.

- Install metal trellises.

- Do not submit the concrete to direct loads.

- Use the new self-curing concrete. This contains beneficial bacteria, which will form plaster and fill in the cracks.

- Others: probe the cracked places with a hammer, dig out the damaged parts and remove them, remove the rust, apply an anti-corrosion product and the mortar, smooth and leave to dry. And areas that sound hollow should be removed. Then remove all the damaged parts until the reinforcements.

Concrete blocks in Poyatos

Do you want to see the range of machinery for treating pre-cast surfaces and for the special finishing of Poyatos concrete blocks?

Well, this includes: splitters, agers for finishing paving stones, shot blasting and bush hammering machines, colour dosing systems, ColorMix systems for the colour wear effect, etc.

1. The semi-automatic spitter

To cut concrete blocks, it is equipped with 4 blades (inside, top and sides).

2. Ageing- Bush hammering machine

It ages by hammering and is equipped with 144 hardened steel hammers.

.jpg)

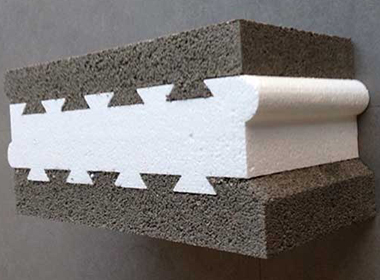

3. Systems for inserting polystyrene sheets

Get better finishes for your concrete blocks with the insertion of injected polystyrene sheets.

4. Offer better finishes to your concrete blocks and paving

Offer the colour you want for your concrete blocks with Poyatos colour dosing systems.