Are you looking for custom concrete projects?

At block machines Poyatos we carry out customised concrete projects and we seek the best solutions for each of our clients. To do this, we carry out a meticulous prior study of the needs and circumstances of each one and then present our solutions. And, as you can read on our website:

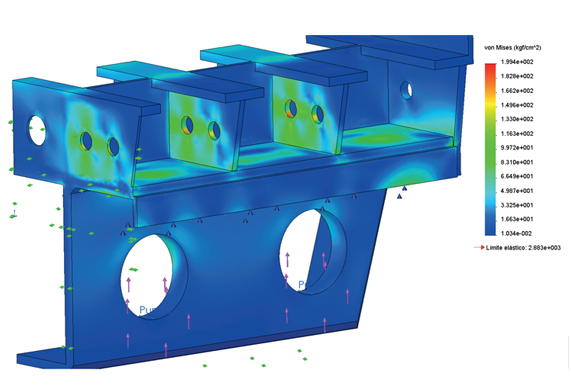

”At Poyatos we care about studying how to optimise our machinery to the maximum for each client. Seeking to achieve the minimum possible wear of spare parts, molds and trays in our Block Machines, block machines, concrete plants, and machinery for special finishing of concrete blocks.”

Large facilities in Poyatos

In addition, we currently have facilities with a covered area of 30,000 m2, equipped with high-tech, robotic and numerical control machinery. And, in our block factory we follow manufacturing processes that allow us to lower costs (which we pass on to our customers) with a high quality finish on our equipment.

It should also be said that, in our concrete projects, all our machinery is manufactured in our workshops. ”We assemble hydraulic and electronic components and embeddable elements from top brands worldwide. All this allows us to manufacture high-quality block machines and high productions with minimal maintenance and that adapt to different needs.”

Block machine manufacturers in Spain

As you already know, at Poyatos we are manufacturers of block making machines for the production of precast concrete and specialists in comprehensive solutions for the implementation of block making factories.

To do this, we design and manufacture under our own patent all the machinery for your custom concrete projects. Among which we find:

At Poyatos we have extensive experience in custom concrete projects and, in addition, we have a large stock of machinery designed and manufactured under our own patent:

High production block machines

Among the high production block machines we have three models: Universal, Megabloc and Novabloc:

Universal: a fully equipped facility

This block machine ”requires a single person to control and supervise. The entire production process is fully automated and managed by computer through software.

We are talking about a completely automatic installation that achieves optimized productions, with low energy consumption. It is also easy to operate and maintain. Below we leave you the video of its operation, and you can download the pdf here with all the information about the block maker.

Megabloc: the highest productivity on the market

We are referring to the machine that can offer the highest productivity on the market (more than 4,500 20 cm blocks per hour, 18 pieces per tray). All thanks to its modular vibration system (patented), powered by a single 45 kW motor, based on 2 independent vibration tables.

These block-making machines provide a large number of possibilities depending on the requirements of each market and client. We leave you a video with its operation, so that you can delve into it, and all the information in the pdf of the machine.

Novabloc: a modular vibration patented by Poyatos

A completely automatic installation, equipped with the modular vibration system, patented by Poyatos. Among its main advantages, we find:

- Energy saving on starts and stops.

- Time savings in starts and stops (about two seconds per cycle).

- That there is no disintegration of material, as the vibration stop is instantaneous.

- Savings in maintenance in all vibration mechanisms.

- The drive is achieved with a single 22 kW motor at 1,500 r.p.m. (normal series engine), without any type of maintenance.

- Automatic regulation of vibration parameters, both amplitude and frequency.

Find out how it works in the following video, and download all the information with this pdf.

Automatic block machines

”At Poyatos we are manufacturers of automatic block machines for the production of custom concrete projects. We offer comprehensive solutions for the implementation of block making factories around the world.”

Prima: the economic block making machine

An economic installation conceived for entrepreneurs from developing countries who aspire to create custom-made concrete projects of industrial quality. It is also suitable for manufacturers in small markets or who want to make some type of special product.

These are block machines with an important production capacity, being also robust and very easy to handle and maintain. Both the production of concrete and the manufacture of parts are automatic processes.

Below we leave you a video with its operation, and the pdf so that you can download all the information.

Syncro: a block machine with minimal maintenance

This model works with a wooden or metal tray and with a length that goes from 1200 mm to 1400 mm and a width from 600 mm to 900 mm. The installation circuit can be configured in line or in the U.

This block-making machine has a 5-height elevator and lowering unit that speeds up the transfer of the trays to the dryers by means of a forklift. With regard to palletizing, you can use a pneumatic or automatic electronic palletizer.

In this video you can see how it works, and in the pdf download all the information about the machine.

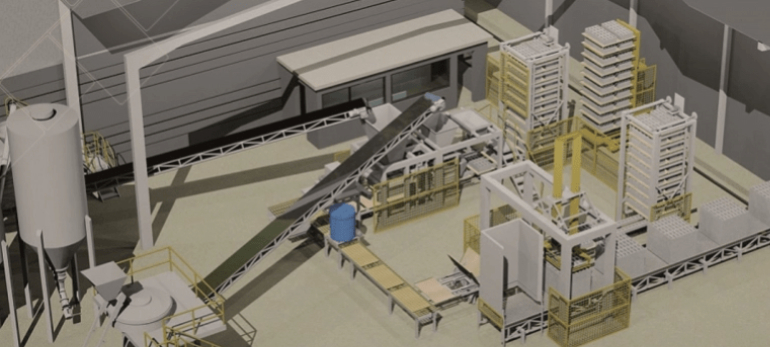

Custom concrete projects: Concrete plants in Poyatos

At Poyatos we offer ”turnkey” factories, and for this, we manufacture concrete plants that carry out the complete dosing, transport and mixing process. In this way, we design and manufacture two types of machines under our own patent:

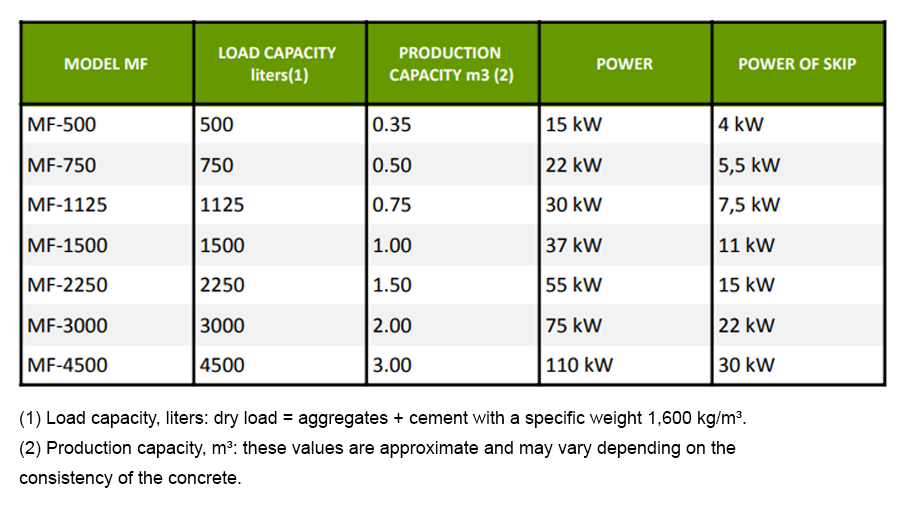

Mixers for Concrete Plants

”In them, the tank is fully covered on the bottom and sides. It has special bolt-on and replaceable anti-abrasive sheet steel plates. The arms of the blades of the Mixers for Concrete Plants are mounted in an articulated manner.”

Its actuation can be manual and automatic, by means of a pneumatic or hydraulic system. In addition, it has the possibility of carrying from one to three discharge gates.

Download here the pdf with all the information, and in the graph below, you will be able to know the production data:

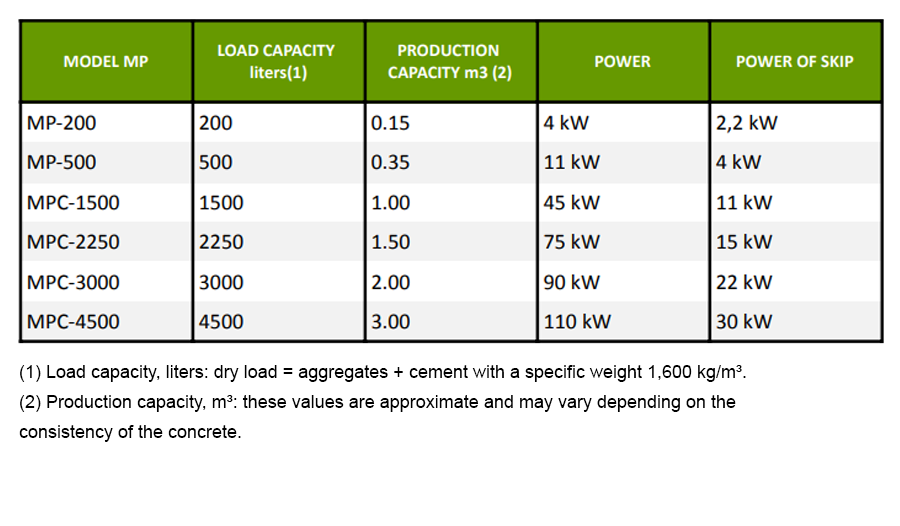

Planetary: State-of-the-art machinery for your concrete plants

Another of our machinery for custom concrete projects. A state-of-the-art mixer patented by Poyatos for concrete plants.

It has a turbine with mixing blades with planetary movement and a group of turbo blades (in turbo-planetary mixers the advantages of a planetary mixer are combined with those of a "turbo": homogeneity and speed of mixing, together with a rapid discharge) .

In the lower image you will be able to know all the production data, and in the following document you will be able to download the informative pdf.

Customised concrete projects: Machinery for special finishes of concrete blocks

Finally, we want to talk about our range of machinery for surface treatment of precast and for the special finishing of concrete blocks.

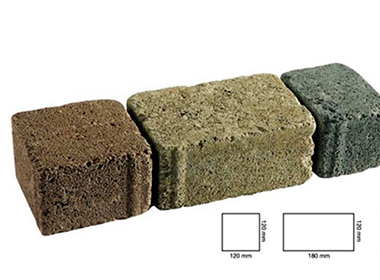

Within this range, you can find: splitting machines, ageing machines for finishing paving stones, shot blasting and bush hammering machines, colour dosing systems, ColorMix systems for the colour gradient effect, etc.

Splitters for concrete blocks

In our block making factory, we have two models for the splitting machines:

Semiautomatic splitter, Mod E-600

The semi-automatic splitter for cutting concrete blocks is equipped with 4 blades (interior, upper and lateral).

Here is the explanatory video of its operation:

Automatic splitter, Mod. A-600/4

In this case, we are talking about automatic operation, equipped with 4 blades: upper, lower and lateral, with mechanically and hydraulically compensated efforts.

You can see all the information in the following video:

Aging – Bush hammering

With our patented paver aging machine (and other pieces on top of these) you can give your cinder blocks an aged touch.

It has an aging procedure by hammering and is equipped with 144 hardened steel hammers.

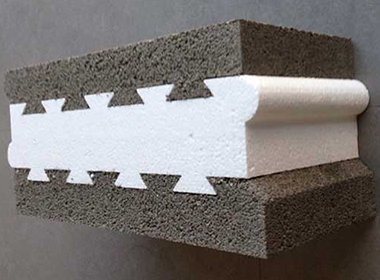

Systems for inserting polystyrene sheets

We continue with our machines to be able to offer customized concrete projects and in this case we are talking about the systems for inserting polystyrene sheets. These are patented for the manufacture of blocks with insulation, in all models of block makers. You can choose a model with automatic or manual execution.

Color dosage for concrete blocks and pavers

Lastly, if you want to give your concrete blocks a different color, at Poyatos we have color dosing and distribution systems for powdered dyes in granules for all models of block machines.

"Within our range of machinery for the treatment of precast surfaces and for special finishing, it includes color dosing systems, ColorMix systems for the color gradient effect, etc."