Do you want to know more about concrete block machines?

Someone could wonder what inspired engineers to create the first concrete block machines. The requirement for structures with several stories became unavoidable by the end of the 20th century due to the exponential rise in population and technological sophistication.

Today, skyscrapers are constructed in many cities worldwide for this precise reason. These high-rise structures are relatively easy to plan and build.

.jpg)

You may be wondering what role concrete block-producing equipment plays. Concrete blocks are used to lighten the load of the building and strengthen it against harsh weather and other natural elements. This is where the concrete block machines comes in handy; it makes the blocks you need.

Concrete blocks are the most famous building material today due to their many advantages over other options. It"s manufactured in an assortment of forms and sizes to serve a variety of functions.

Different Forms of Concrete Block Machines:

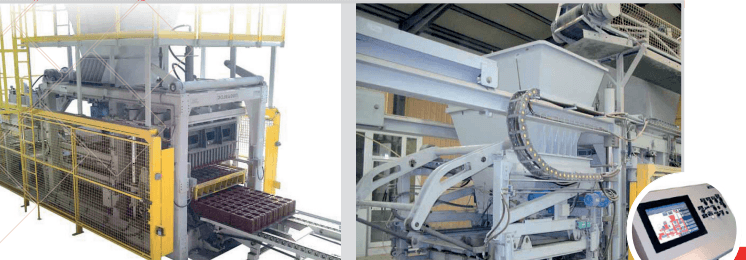

The concrete block making machine will present a manageable learning curve if you go for a fully automated or semi-automatic model. Because of the small stones, cement, and heavyweight mortar that are utilized in this block-forming machine, it is necessary to have a machine that possesses a high level of mechanical strength and durability.

Different concrete products can be formed with a concrete block machine by applying pressure and vibrating the mould.

Based on their operational principle, two types of block-producing machines may be distinguished:

1. Mobile Concrete Block-Making Equipment:

This tool might also be referred to as a mobile bricklayer. Like any other machinery, it has its advantages and disadvantages, such as a smaller footprint and a lower capacity than its stationary counterparts. The full article on the bricklaying machine will go into greater detail.

2. A Concrete Block-Making Machine that Remains in One Place:

There must be a solid concrete base for this apparatus. Pallets are used in this concrete product-making machine. Depending on your needs, budget, and the regulations of the country where you plan to set up shop, you can choose from a variety of stationary block-building machines, often known as brick-making machines.

Positives of a Permanently Installed Concrete Block Machine

1. Several Mold and Item Options

This machine can make pavement, hollow concrete, curbstones, roof gutters, lawn stones concrete blocks. About 600 different mould are available for stationary concrete block production machines.

The only things left to do are place an order for the mould and install them on the concrete block machines.

2. The Varying Degrees of Automation:

You can customize the degree of automation of your block production machine to meet your needs and your budget. Semi-automatic machines are suggested purchases for developing nations with low labor costs, while fully-automatic models are suggested investments for industrialized countries with high labor costs.

- Delivery of pallets to the curing area is handled manually in a semi-automatic machine. Still, it is dealt with automatically in fully-automatic concrete block-producing machines by forklifts and pallet-collecting robots (stacker robots).

- An automatic concrete block-making machine may cut down on the required curing space.

- This robot stacks five pallets high, takes them to the drying area and then returns them. This means your site"s curing area can be half its current size. Automatic machinery is more prevalent in industrialized nations because of the high cost of land.

3. Maintains Consistency in Quality

With the stationary concrete block-producing machine"s automatic weighing mechanism, you can be assured that the quality of your concrete product will remain consistent at all times and that your clients will be pleased with it.

4. Produce Paving Blocks with Two Layers

When a second hopper is attached to a concrete block-making machine, it may create paving blocks with two layers. It is also known as a paver block machine. Double-layer paving blocks are superior because the top layer can have a different color, and the surface can be made smoother by combining smaller raw materials.