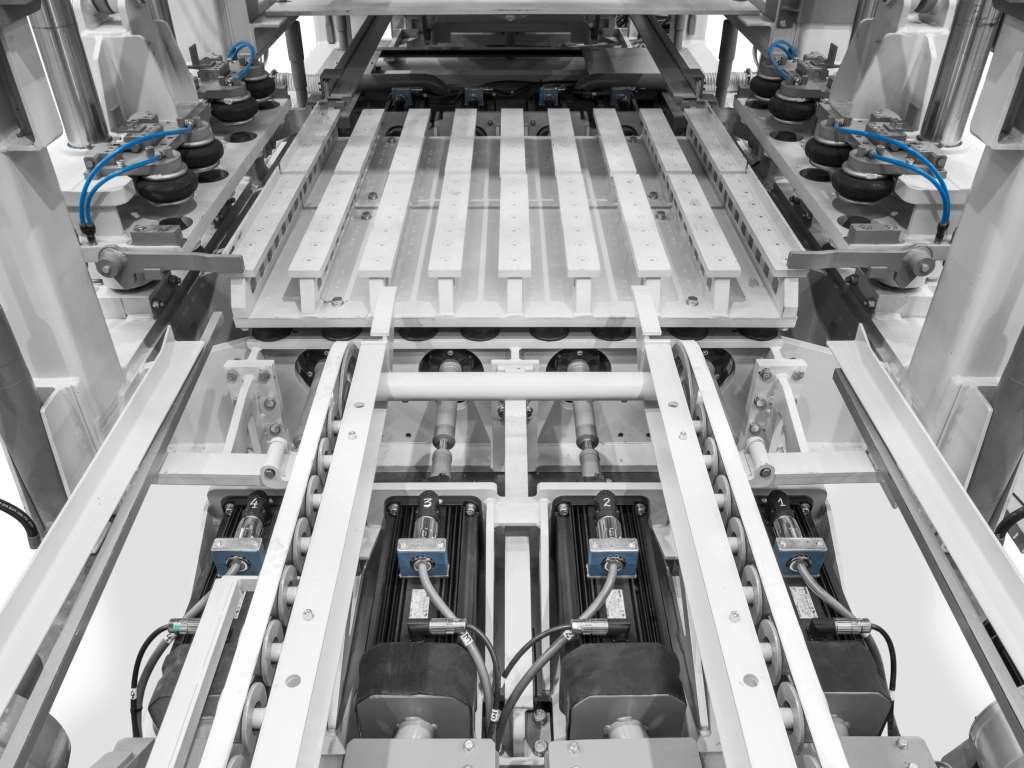

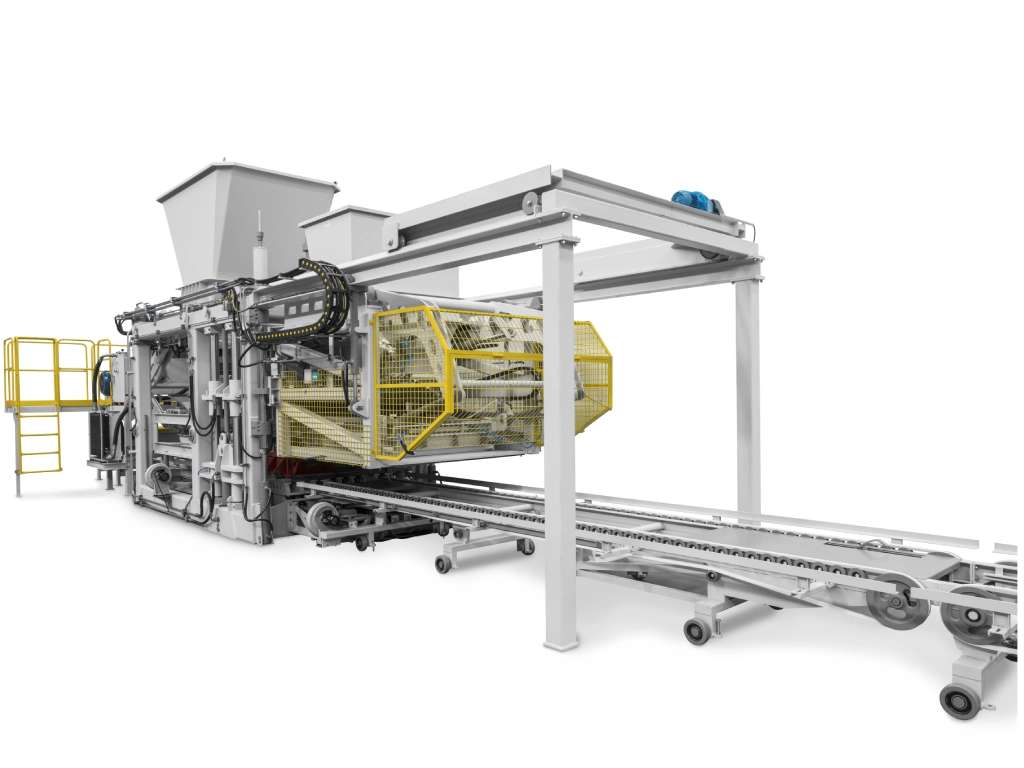

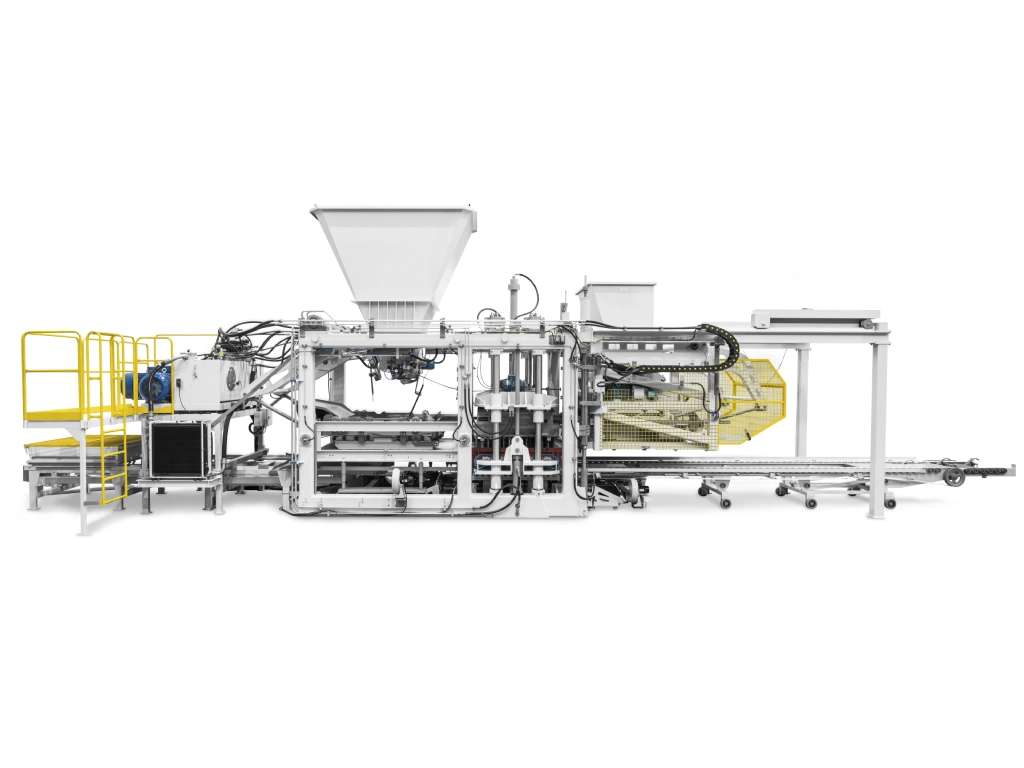

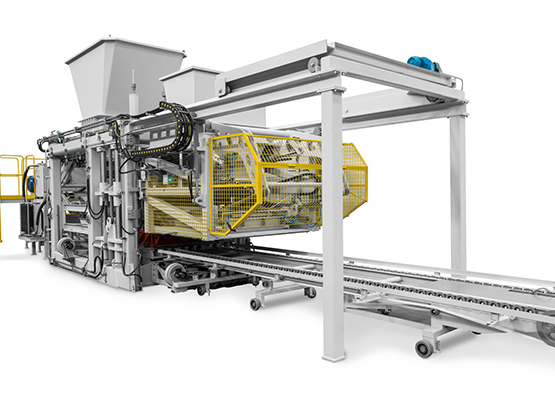

The Concrete block Machine, Megabloc stands out for providing the highest productivity, 18 blocks of 20 cm (8”) per cycle (up to 4500 blocks per hour), thanks to its servo-driven vibration system with two vibrating tables, that allows a balanced filling of the mould as the parameters of vibration at each one of the tables are adjusted independently.

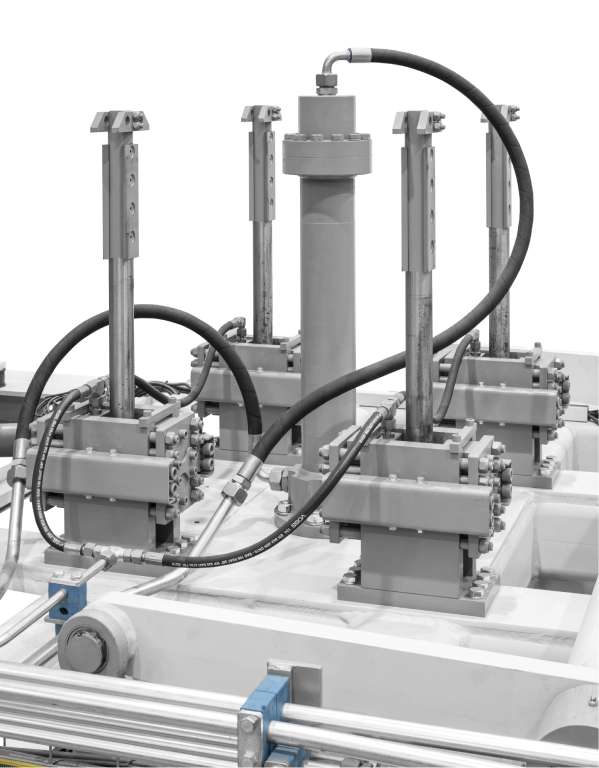

The servo-driven vibration system consists of 2 vibrating tables equipped with 8 servo-motors (4 servo-motors with 4 eccentric masses per each table) allowing for exact control of all vibration parameters: frequency, amplitude, speed of phase changes, etc.

The Megabloc concrete block machine can run on either wood, steel, or plastic production boards ranging from 1200 mm to 1500 mm (47” to 59”) in width and in depth. Optionally, it can be equipped to manufacture face mix products.

Handling and transport of the production boards is done by an automatic finger car that can be customized in terms of height, load, turning capacity and operating speed. A manual or automatic buffer system for production boards can be included as well.

The Megabloc line includes an automatic electronic cuber/palletiser, held by a double central column, with high speed lateral and up & down movements with a "closed loop" controlled movement system which allows shorter operating times and reduced electrical consumption. The independent clamping from both directions is controlled by encoder to apply to each product the right pressure parameters, duly saved for each product at the running program. Optionally, the palletizer can be equipped with a vacuum system for stacking thin pavers and slabs.

There is a wide range of options to remove the packages with products out of the line according to the requirements of each project, such as roller track conveyor, slat conveyor or railway wagon.

Customized software program provides all kind of information about the machine performance, maintenance, management data (output, consumption of materials, incident notices…). The touch screen allows an easy and intuitive management of the program. Online support service allows the remote access to the program in the event of dire incidents if required.

TECHNICAL DATA

- Size of production pallets: (1200 - 1500) x (1200 - 1500) mm.

- Useful working area: (1120 - 1400) x (1120 - 1400) mm.

- Height of the products: from 25 to 400 mm.

- Cycle time: 12 - 16 seconds.

- Average production of 20 x 20 x 40 cm (8”) blocks per hour: 4000 - 4500 pcs.

- Average production of 20 x 15 x 40 cm (6”) blocks per hour: 4800 - 5400 pcs.

- Average production of paving stone blocks (single layer) per hour: 330 - 370 m2.

- Minimum area for the plant (for equipment and curing chambers): 2000 m2.

VIBRATION

- Two vibrating tables.

- Servomotors with independent forced ventilation for continuous operation.

- Greased in permanent oil bath (minimum maintenance).

- Maximum vibration force: 200 kN.

- Power: 8x15 kW.

- Power upper vibration: 2x5,5 kW.

HYDRAULIC GROUP

- Cooling by air.

- Power: 2x45 kW.

| CYCLE PARTS | PRODUCTION PER HOUR*** | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| MODEL | MAXIMUM* PALLETS SIZE (mm) | USEFUL PRODUCTION AREA | CYCLE TIME** (sec.) | PAVERS 10X20 (pcs) | BLOCKS 15X20X40 6” | BLOCKS 20X20X40 8” | PAVERS (single layer) 10X20 (sqm) | BLOCKS 15X20X40 6” | BLOCKS 20X20X40 8” |

| MEGABLOC | 1.400 x 1.350 | 1.300 x 1.300 | 14 | 66 | 24 | 18 | 370 | 6.200 | 4.629 |

* The size of the production pallets (wooden, steel or plastic) may be tailored according to the requests of each project.

** The cycle time is for guidance only and may vary depending on the type of product, quality of the aggregates, staff and other factors related to the production

*** The hourly production is for guidance only and it is calculated at 100% of the capacity of each machine.